ACME Dynamic Motion Seat Fighter Product Line

F-16 ACES II

T-6

F-15 ACES II

T-50

M346

T-7

Fighter Type Dynamic Motion Seats

Fighter Seat Types

ACME makes many different types of motion seats for fighter jet simulators. We make seats to replicate both foreign and domestic ejection seats. We make motion seats to emulate Martin-Baker or ACES type ejection seats. ACME has six different, completely COTS motion seat designs available. And we can easily build other seat types to meet your project needs.

The core, patented technology of the True Q® DMS system remains unchanged so we only need to update the external features to build a new seat type. ACME DMS are used in fighter simulators in Italy, Singapore, Mexico, New Zealand, Turkey, the United States and other countries.

Fighter Ejection Seats

Motion Seats that Look, Feel, and Function like the Actual Ejection Seat.

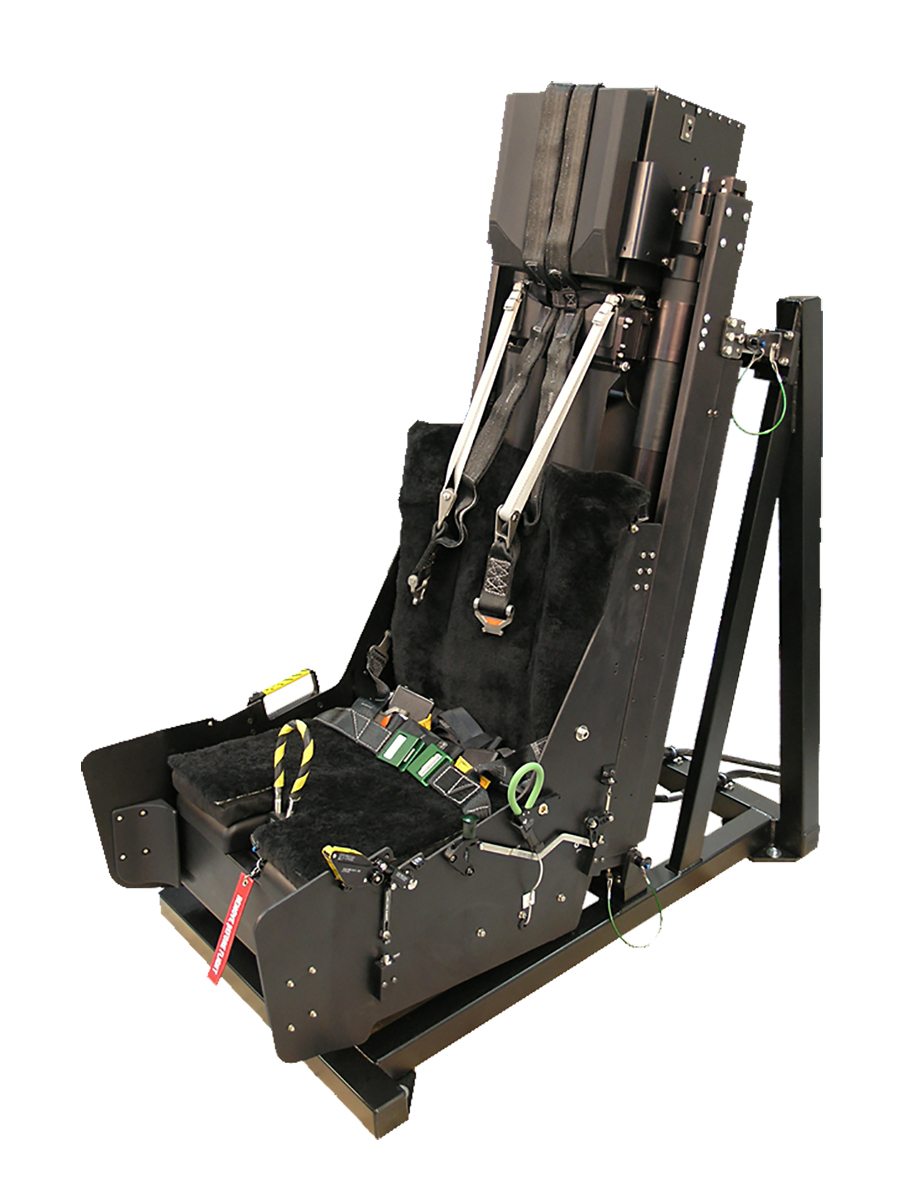

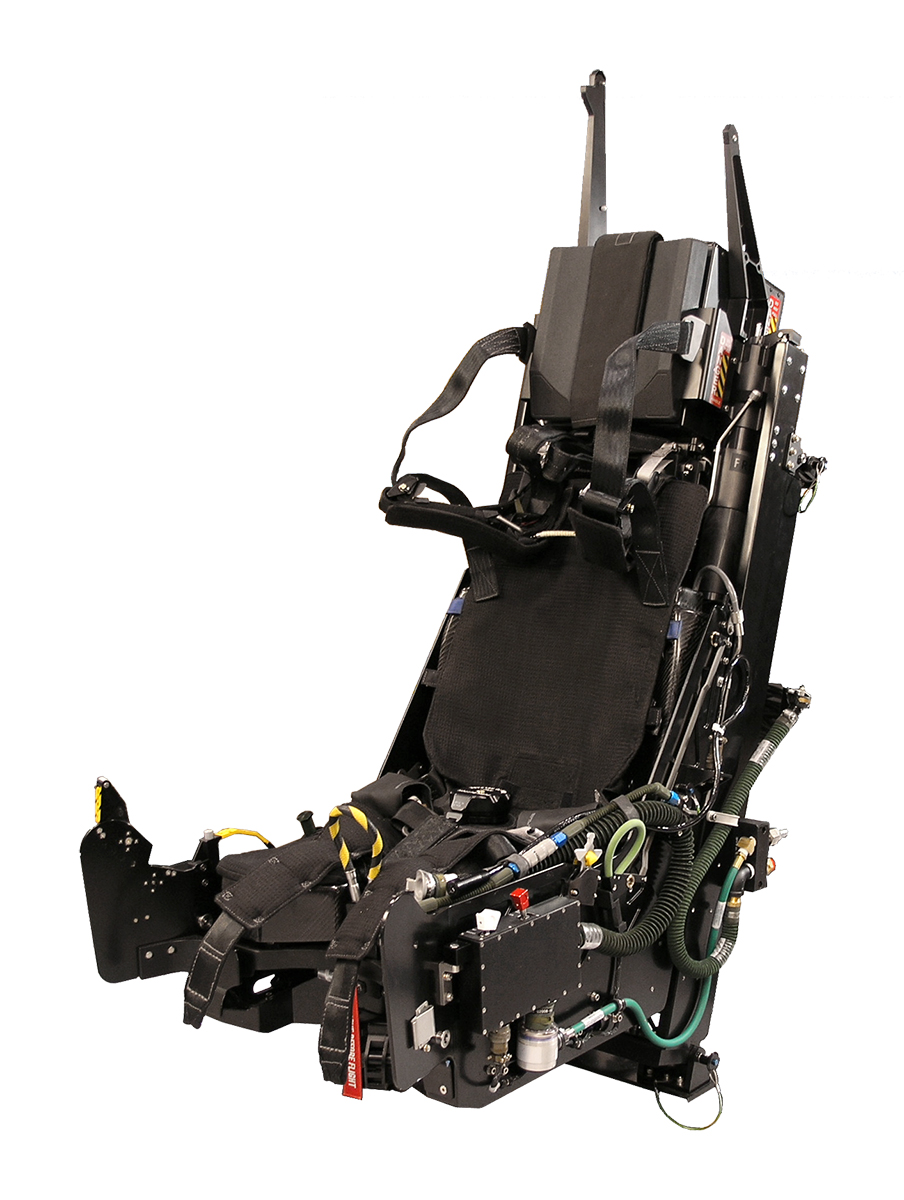

Fighter jet pilots sit atop ejection seats in the jet. Ejection seats are complex devices that provide a rocket-powered escape in an emergency. Because ejection seats include a powerful rocket, the seats have unique features to control the ejection. The seat has elements for arming, safing, initiating, and firing the rocket to eject the seat. Ejection seats also include a seat height motor because the seats are very heavy. To secure the pilot in the seat and to the parachute, ejection seats include lockable crews harnesses. And, there can be life support connections such as mask air or G-suit connections.

True Q® DMS fighter seats mirror the ejection seat’s features, controls, and connections. ACME licenses Martin-Baker engineering data to build motion seats like their ejection seats.

The DMS include the harnesses, buckles, and inertial reels that lock the harnesses when under G-loads. The crew also can manually lock the harness; the cushions and headrests are included, too. Options for leg retractor harnesses and survival kits are available.

The DMS can look, feel, and function just like the ejection seat (minus the rocket-power!). Or we can build a more generic fighter seat to suit your budget or training needs. ACME can help you specify a seat that meets your unique needs.

All Motion Components Inside the Replica Ejection Seat

With True Q® DMS, all the motion components are inside the seat. All the motors, linkages, and motion plates are built in the seat body—nothing is below the cockpit floor. The DMS is the same size and shape as the ejection seat and fits right into the simulator cockpit and mounts on the bulkhead like the ejection seat.

Dynamic Motion Seat G-Suit Systems

ACME Simulator G-Suit Systems – Training for G’s without the Actual G’s

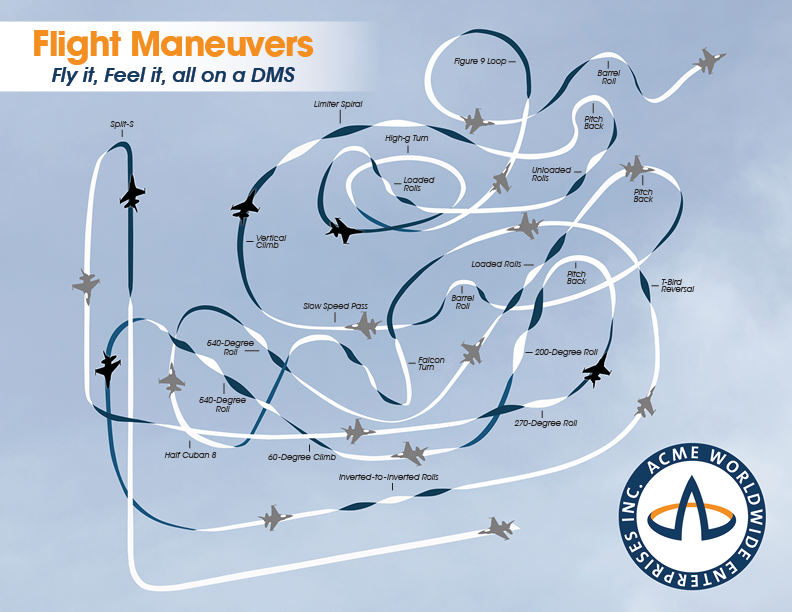

Fighter jets operate in a dynamic world of banks, climbs, dives, rolls, vibrations, shudders. The jet continuously changes accelerations and G-forces. G-loads are an inseparable part of the fighter environment.

Pilots use the cues from the motion, pressure, and vibrations to fly the jet. The flight sensations are part of the pilot’s awareness of the jet’s status and situation. And, G-suit pressure is a companion to the G-loads in flight. Outside of the centrifuge, there is no way to apply flight G-loads to the crew in the simulator. But, G-suit pressure is an excellent way to train sustained G-cues. In flight, G load is either constant, increasing, or decreasing. The pressure in the G-suit starts at specific loads then varies according to G-Load above the pressure onset.

Thus, the varying pressure can be used to cue varying G’s in the simulator. Since the crew knows G-load at the onset pressure for the suit, the crew has a baseline cue. Increasing pressure above the G-suit onset signals that G’s are increasing. Decreasing suit pressure signals decreasing G-loads. The G-Suit pressure scale in the simulator mirrors the pressure scale in the aircraft.

So, the amount of pressure in the suit signals the specific G-load. And, specific G’s are training cues. Specific or targeted G-Loads are often elements of the fighter mission. For example, pop-ups from nape of the earth to target, and ordnance release might be limited to specific G-loads. Roll outs from the target or the overhead break in the airfield pattern can also be g-specific. G-Suit pressures can cue the specific G-loads for training.

In fighters, speed (energy) is life. G-Cues can help maintain energy.

In the simulator, it’s easy to lose the sensation of the energy drop in heavy maneuvers. This can lead to holding tight turns until airspeed bleeds off to dangerous levels. Poor energy management habits learned in the simulator can be transferred to the jet. G-suit pressures help reinforce the maneuver’s effects on energy in the simulator.

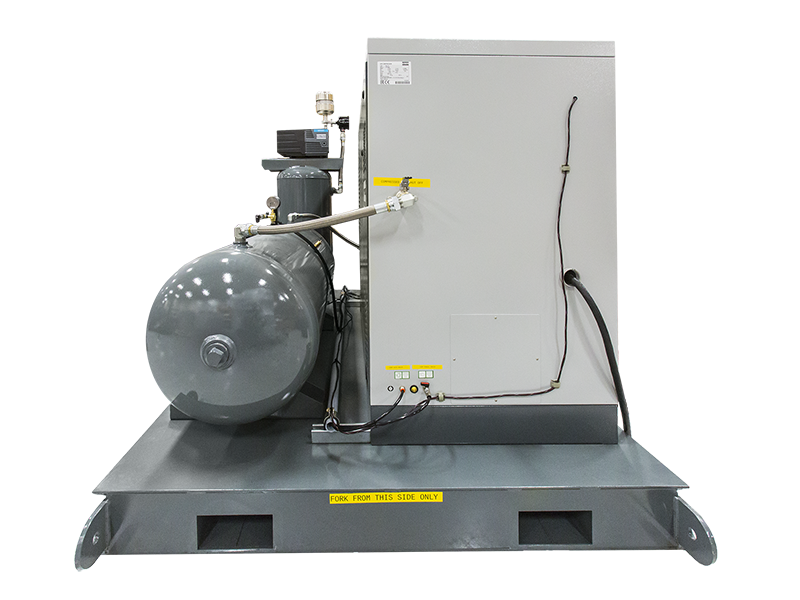

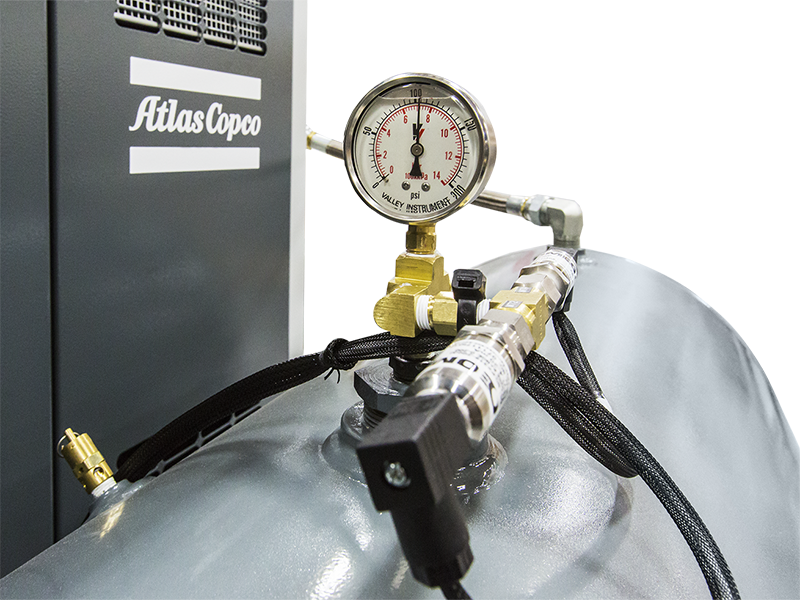

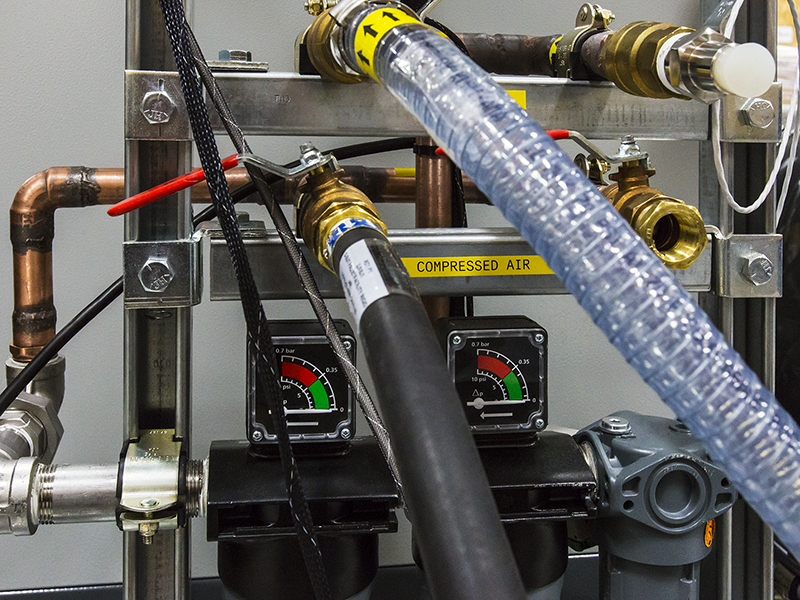

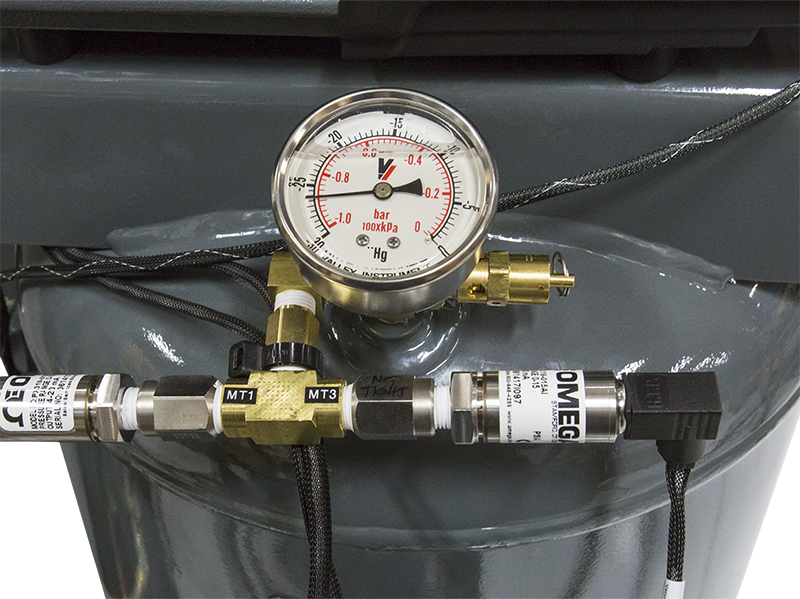

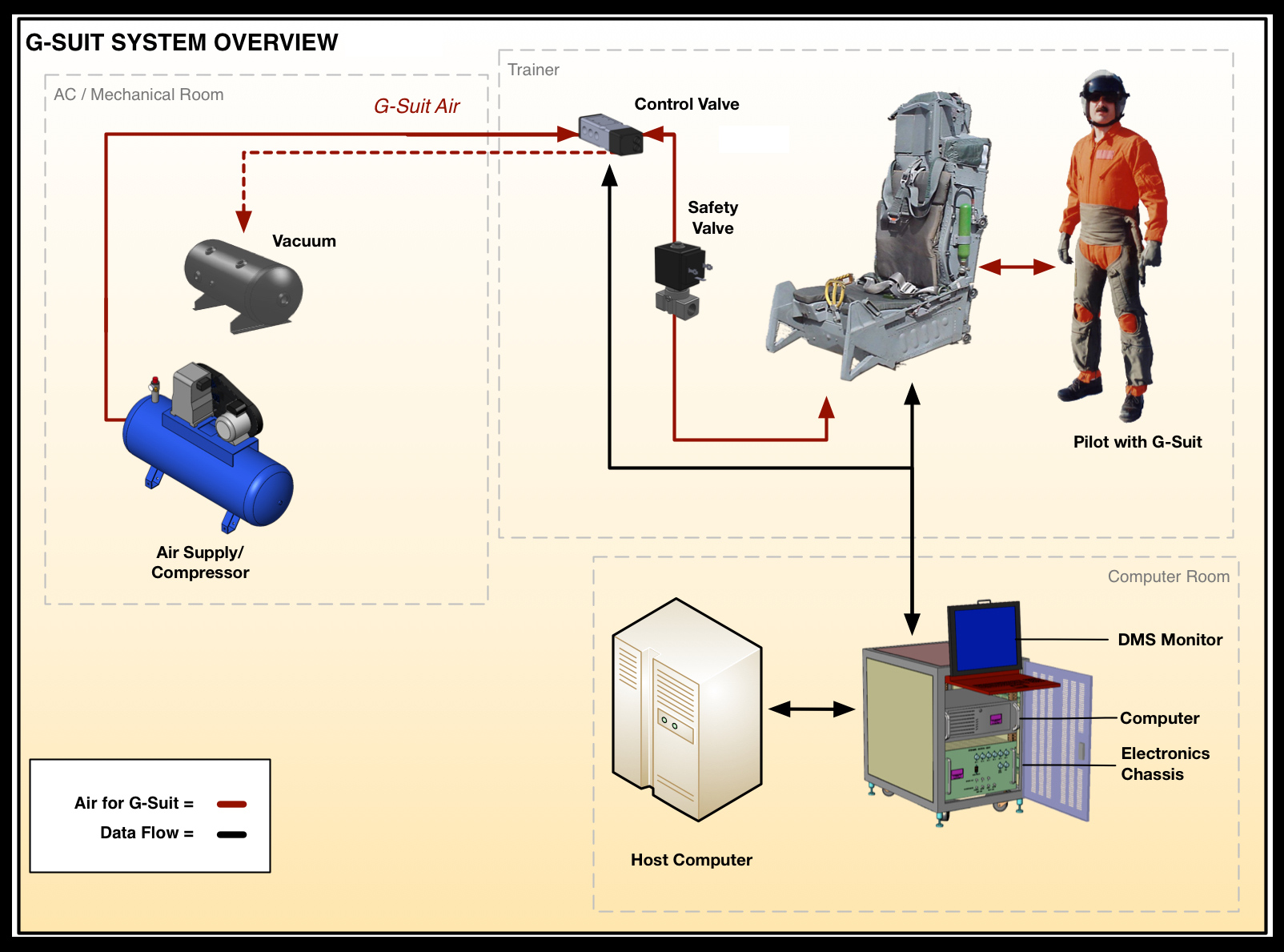

ACME’s G-Suit System for simulators provides exceptional cueing for G-loads. The system is designed as a drop-in option for ACME’s fighter type Dynamic Motion Seats. It’s also available as a stand-alone system for simulators. ACME’s G-suit system is a complete, turnkey option including compressors, valves, filters, and tanks. Systems are available to support differing needs. The system can support a single G-suit. Another configuration supports twin pilot copilot G-suits working together in the same simulator. Systems can even support multiple, independent G-suits in different simulators.

The system uses pressure and vacuum components to rapidly inflate and deflate the G-suit in response to simulated G-forces. The G-suit pressures in the simulator system match the same proportional scale as the G-suit in the jet. The system uses the same computer that drives the motion seat. Integral software translates simulator acceleration signals into specific G-suit pressures.

ACME’s G-Suit system is complete.

It includes an electric compressor, wet and dry receiver tanks, vacuum tank, filters, driers, valves, regulators, and automatic drains. It includes all equipment needed to provide controlled pressurization for realistic G-cues. The stand-alone compressor can be remotely located and controlled from the simulator. And the system can be set to achieve pressures desired by the customer.

Complete system includes the high-flow compressor, pressure and vacuum tanks, controllers, filters, valves and more. Entire system is easily controlled via the DMS Computer and needs no direct inputs during ‘flight’ operation. Extended cables and hoses enable the Pneumatic pallet to be remotely located from the cockpit such as in a utility room. Valves on board the cockpit provide direct connection to crew g-suit ensembles.